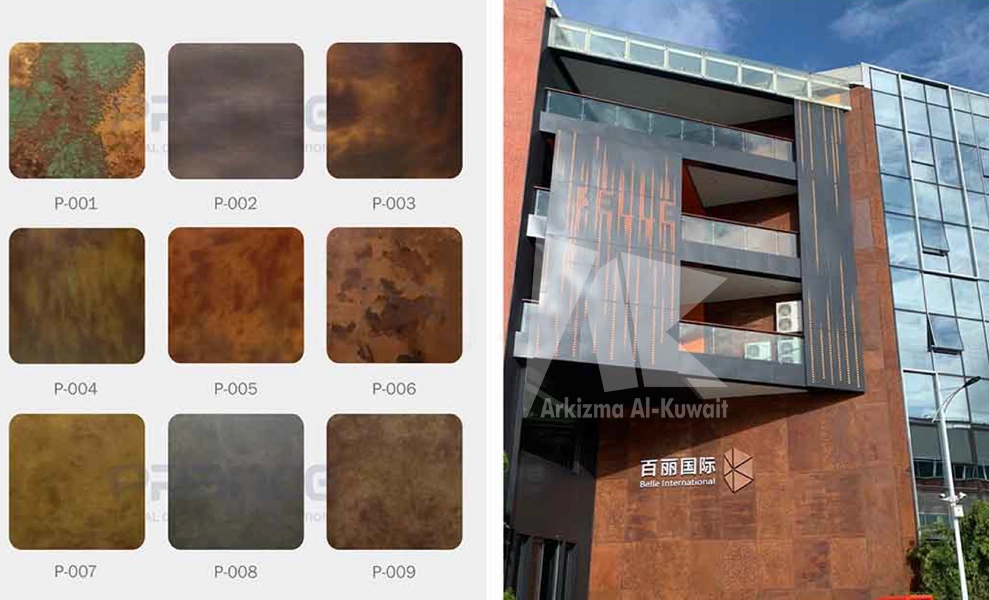

ANODIZED SURFACE FINISH

Anodizing is a surface treat ment that enhances the natural beauty of metal decorative panels while also providing 1durability and resistance to corrosion. The process integrates colors into the metal, rather than painting then, on, resulting in a finish that retains the natural metallic appearance of the material.

Durable

Up to 20 years warranty letter can be provided by the aluminurn anodizing material manufacturer.

Metallic Look

he natural metallic appearance and feel of the aluminum are fully preserved.

Cost Effective

Anodizing metal panels generally applied and seem in premium commercial areas which bring up the areas Into high-class.

Many Option

Different textures such as regltlar. bright, brush. milling and color.

Fire Reaction

Eu reclass B-s1, dO Eutocias A2-s1, dO EN 13501-1

Weather Resistance

Corrosion Resistance, Abrasion Resistance. No risk of adhesion failure, No possibility of fading or c11alking.

Anodizing is an electrochemical process that transforn1s the surface of a metal into a decorative, anodic oxide finish. This finish can provide a wide range of colors and finishes, rnaking it a popular choice for custon, metal decorative panels in architectural and comn1ercial buildings.

In architectural and comn1erc1al building applications. the anodizing finish is often preferred over other surface finishes such as painting and powder coating because it preserves the metallic look of the metal panels.